Supplier Relationship Management: For Dummies

And You!

By: Sam Jenks

Supplier Relationship Management:

3 words and 32 letters that hold a lot of meaning for businesses and their supply chains. I’d dare to say, few individuals really understand the interworking of SRM or the implications a Supplier Relationship strategy can have for a corporation and it’s supply chain.

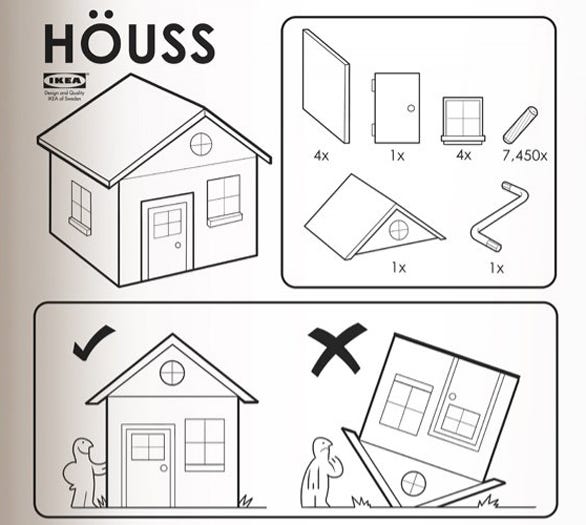

When I get a new piece of furniture from IKEA I typically pull out all the pieces, assort them in their prospective groupings, grab a screwdriver or any other necessary tools, and take a look at the instructions.

I follow the steps laid out for me on paper to alleviate stress, avoid mistakes and optimize the lifetime that piece of furniture will spend in my apartment. Sparing me the exertion of time and money in the future.

I plan to treat this post like your personal set of IKEA instructions. I’m going to give you information to build a better understanding of Supplier Relationship Management, step-by-step, basic as they come, creating a sturdy wardrobe, backed by well-accrued knowledge.

This article will not leave you flustered, missing 4 screws, in a fight with your significant other, and/or saying, “Where the hell was this piece supposed to go?”

This is Supplier Relationship Management For Dummies!

Definition please!?

Take it away ISM:

“The term “supplier relationship management (SRM)” refers to the practice and process for interacting with suppliers.”

Thanks for that, and your thoughts CIPS?

“Supplier Relationship Management (SRM) is a comprehensive approach to procurement managing and capturing the post contract value from key business relationships.”

Building a definition behind the term is the first step to better understanding it’s potential for adding value in your business.

So, what does SRM do?

Supplier Relationship Management functions to better the relationship between buyer and supplier.

Focus on this relationship is paramount for effective levels of compliance and transparency bettering brand value with stakeholders and consumers. Trust and honesty throughout all buyer-supplier communication creates a situation to create common value and gain.

Higher levels of communication in the buyer-supplier relationship make for more effective sourcing and procurement initiatives. Paralleling beliefs during manufacturing, production, purchasing, and after-production value/logistics generates efficiency and yields faster time to market (cips.org 2015).

Spending time building meaningful relationships with reliable suppliers saves your business the time spent cutting the defective ones out of the picture.

Reduce Risk

You’re getting the gist, right? Good.

SRM, when conducted in a correct manner, creates long-lasting and mutually beneficial relationships.

Understanding and communicating with suppliers can better your chances to reduce risk and capitalize on opportunities in your supply chain functions.

Teams that put a greater emphasis on qualitative and quantitative supplier data analysis will be able to quickly and succinctly identify weak spots, risks and opportunities in the global supply chain — improving the strategies and plans needed to manage the suppliers, and ultimately both businesses, for continued success (cips.org 2015).

Innovate

SRM betters the opportunity for innovation through stronger buyer-supplier collaborations. “Studies have found the top procurement teams that have successfully aligned with their key suppliers have improved supplier capabilities of innovation, quality, reliability and costs/price reductions and agility to reduce risk factors” (cips.org 2015)

Success, when practicing SRM, is created in a manner less likely to be achieved by an individual party.

How do I start practicing SRM in my business?

The same way you learn how to tie a tie, play the guitar or get up on a surfboard.

Look it up on Youtube. Ok, maybe not on Youtube.

But,

Technology is definitely creating a new frontier for more efficient SRM. Software companies are popping up left and right offering services to further the functionality and feasibility of managing suppliers in large global supply chains.

Centralization of information and results regarding suppliers’ compliance, performance and sustainability eases the workload for your procurement and sourcing managers.

Most software options offer features that virtually perform tasks for your business “such as providing all your suppliers’ updated profiles, managing and monitoring supplier performance, and identifying and accommodating new suppliers” (businessbee.com).

Where can I find SRM software?

Learn more about SRM solutions at sites such as Capterra. These sites allow a platform to compare and contrast the strengths and weaknesses of various software companies spanning across multiple areas of use.

The automatic element software adds to SRM’s functionality is exciting, and slowly becoming necessary. However, this shift doesn’t mean that human to human interaction isn’t, still, required at times of auditing, sustainability reporting, performance and/or quality check up’s.

You are no longer dummies, nor were you before the article started my beloved readers.

Until next week.

Check out Kodiak Rating’s SRM Software at